FX & CFX FLEXIBLE PRESSURE TUBE

| FX & CFX Flexible Pressure Tube |  |

Flexelene tubing combines the excellent inert qualities of polyethylene with the flexibility found in 78A durometer PVC tubing. Flexelene is manufactured without the use of plasticizers, and has been designed for use with single barb fittings to offer an outstanding economical alternative to rigid polyethylene tubing systems.

Applications:

- Pure water transfer

- Water Conditioning

- Drinking water and bottling lines

- Brewery lines

- Wine Transfer

- Beverage Transfer

- Deionized Water Handling

Features and Benefits:

- Polyethylene based polymer – a standard class of material used in the water industry

- Pressure ratings similar to, or higher than, those of comparable polyurethane and PVC tubing

- Far exceeds the pressure capabilities of silicone

- Significantly more flexible than standard polyethylene tubing

- Typical working temperature range -40°C to 76°C

- Impact resistant at low temperatures – maintains flexibility to -40°C

- UV stable with excellent ozone resistance – Suitable for use with deionized water

- Contains no toxic plasticizers and is silicone free

- Abrasion and chemical resistant

- Economical

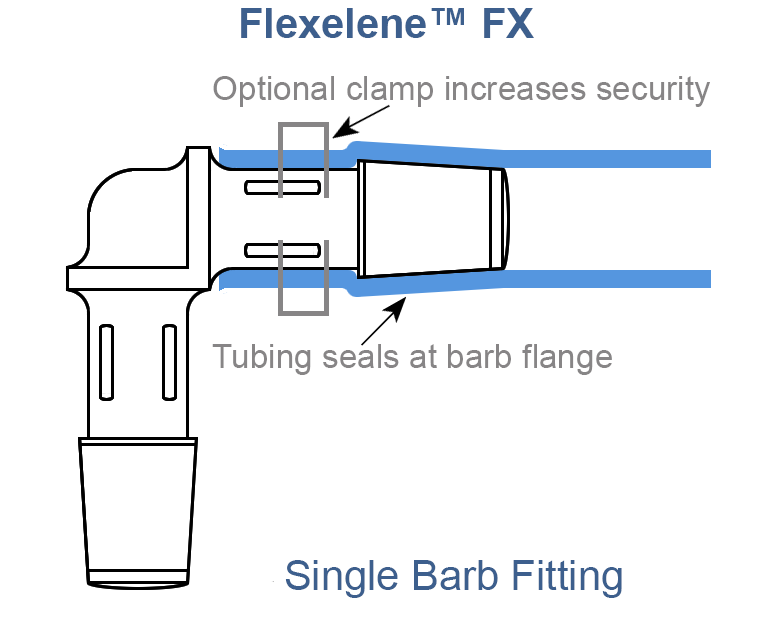

Flexelene FX

Tubing is designed for use with barbed fittings and is compatible with most standard barb sizes. The inside diameter of the tubing is sized so that single barb fittings fit easily into the tubing. Flexelene FX tubing is recommended for use with barbed fittings only.

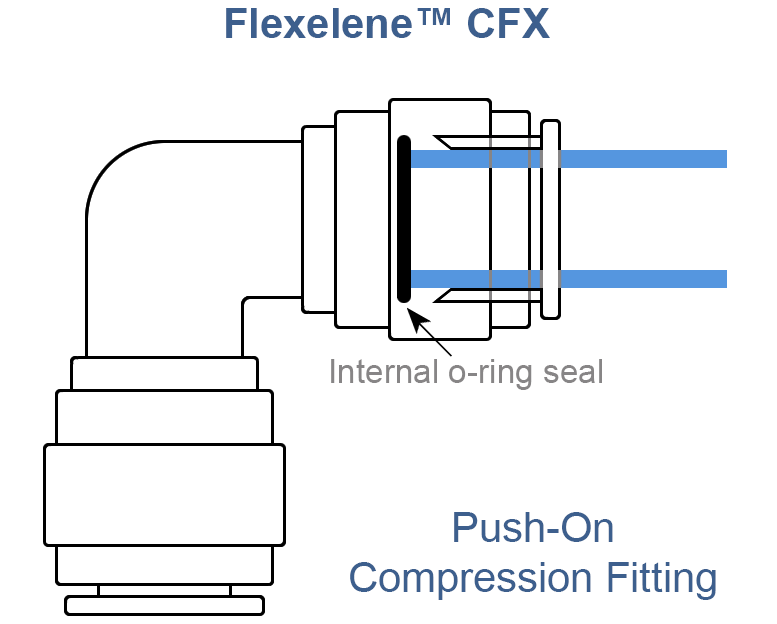

Flexelene CFX

Tubing is designed for use with compression or push-in style fittings. Flexelene CFX tubing is sized so that the outside dimension of the tubing is compatible with push-on fittings. This type of fitting seals with an O-ring against the tubing’s outer wall. Single barb fittings can be used with Flexelene CFX tubing: however, glycerine, water, soap, alcohol or some other type of lubricant may be required to facilitate insertion.

System Design Using Flexelene CFX and Push-On Compression Fittings

Flexelene CFX tubing offers thes advantages over rigid tubing when used with push-on fittings:

- The tubing’s inherent flexibility can alleviate lateral stress, a primary cause of leaks in push-on connections.

- Flexible tubing dampens vibration and shut-off water hammer in system.

- Design of a system can incorporate both push-on and barbed fittings when Flexelene CFX is used

- Because it bends, using Flexelene tubing can reduce the number of fittings required for most installations.

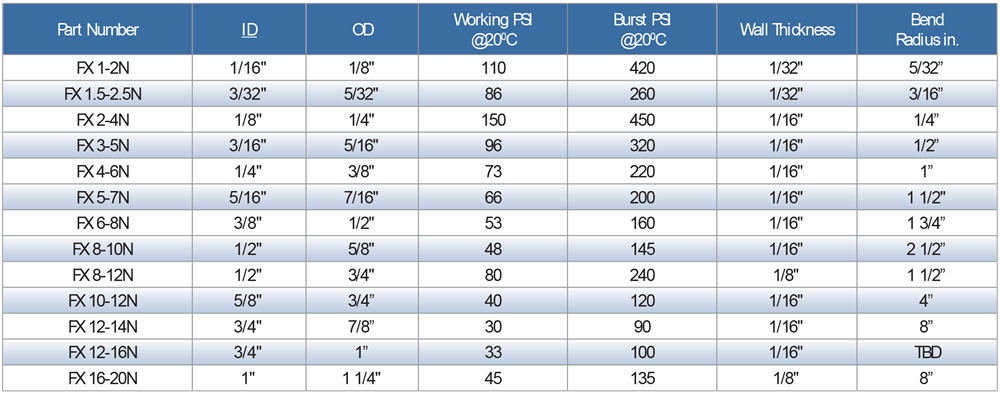

Flexelene FX Tubing Burst pressures are approximately 3 times the maximum working pressure. Higher temperatures will reduce the available working pressure. Results are based on tests at our facility under controlled conditions; therefore, Eldon-James Corp. makes no warranty or claim as to the performance of Flexelene in a specific application. It is strongly recommended that application-specific testing be done, particularly in situations where pressures approach the listed working PSI.

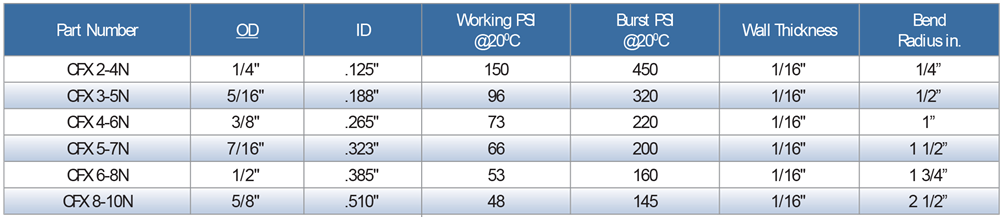

Flexelene CFX Tubing Burst pressures are approximately 3 times the maximum working pressure. Higher temperatures will reduce the available working pressure. Results are based on tests at our facility under controlled conditions; therefore, Eldon-James Corp. makes no warranty or claim as to the performance of Flexelene in a specific application. It is strongly recommended that application-specific testing be done, particularly in situations where pressures approach the listed working PSI.