PharMed BPT

| Biocompatible Peristaltic Pump Tubing |  |

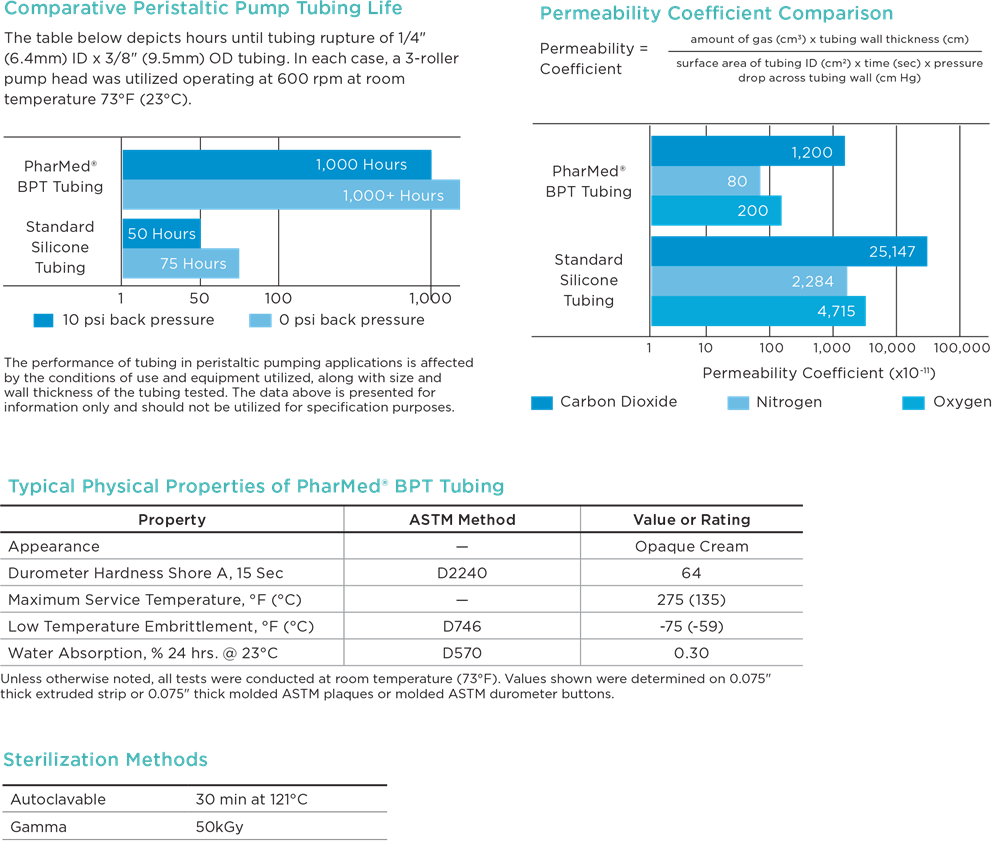

High Performance Peristaltic Pump Tubing PharMed® BPT tubing has been formulated to withstand the rigors of peristaltic pumping action while providing the biocompatible fluid surface required in sensitive bioprocess applications. With its superior flex life characteristics, PharMed BPT tubing simplifies biopharmaceutical manufacturing processes by reducing production downtime due to pump tubing failure.

Simplifies Cleaning and Sterilization

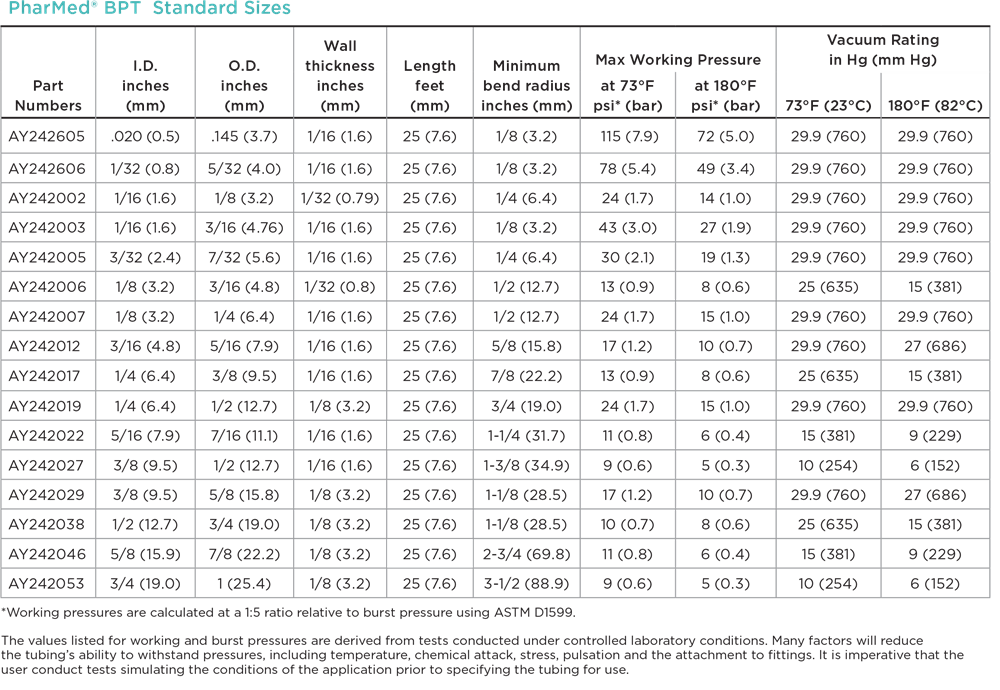

PharMed® BPT tubing is ideal for use in clean-in-place and steam-in-place cleaning and sterilization systems. It is compatible with virtually all commercial cleaners and sanitizers and can be repeatedly autoclaved up to five cycles without affecting overall service life. PharMed BPT also withstands 50kGy of gamma radiation with minimal effect on physical properties.

Superior Barrier Properties

PharMed® BPT tubing is less permeable to gases and vapors than silicone tubing. It is ideal for protecting sensitive fluids in a variety of biopharmaceutical operations including media mixing, cell culture, harvest, and purification. PharMed BPT tubing has very good general chemical resistance and excellent acid, alkali and oxidation resistance. Opaque to visible and UV light, PharMed BPT tubing will help to protect light-sensitive fluids.

Fully Characterized and Biocompatible

PharMed® BPT tubing comes complete with biocompatibility, physiochemical and extractable testing which can be found in the Validation Guide Summary on the Saint-Gobain Bioprocess Solutions website.

Features/Benefits

- Outlasts silicone tubing in peristaltic pumps

- Withstands repeated autoclaving

- Withstands repeated CIP and SIP cleaning and sterilization

- Documented Biocompatibility

- Multiple Manufacturing sites

Typical Pump Applications

- Cell harvest and media process systems

- Bioreactor process lines

- Production filtration and fermentation

- Aseptic filling

- Shear-sensitive fluid transfer

- Diagnostics and laboratory testing