Tygon SPT-3350

| Food and Beverage Transfer |  |

The inner surface of Tygon® SPT-3350 silicone tubing has been designed to reduce the risk of particle entrapment and microscopic build-up during fluid transfer. In-house analysis of the inner surface of Tygon® SPT-3350 silicone tubing compared to other silicone tubing shows that it is up to three times smoother. A smoother fluid path also helps to facilitate complete sanitation of a fluid transfer system. Even in repeat use applications, Tygon® SPT-3350 silicone tubing may prevent residue build-up, aiding in complete cleaning and sterilization. Additionally, the smooth inner surface of the Tygon® SPT-3350 silicone tubing improves fluid flow characteristics by reducing surface area.

Lower Extractable

Tygon® SPT-3350 silicone tubing is produced from a platinum curing process to meet the most demanding requirements of food and beverage sanitary standards. In-house extractability tests have shown that Tygon® SPT-3350 silicone tubing has a low extractable content. Lower extractable help to maintain the integrity of the transported food and beverage media. Tygon® SPT-3350 tubing meets FDA 21 CFR 175.300 and NSF 51 certification. Tygon® SPT-3350 silicone tubing has a Master File with the U.S. Food and Drug Administration.

Features and Benefits

- Ultra-smooth inner bore reduces potential for particle entrapment

- Minimal extractable help maintain fluid integrity

- Excellent fluid flow characteristics

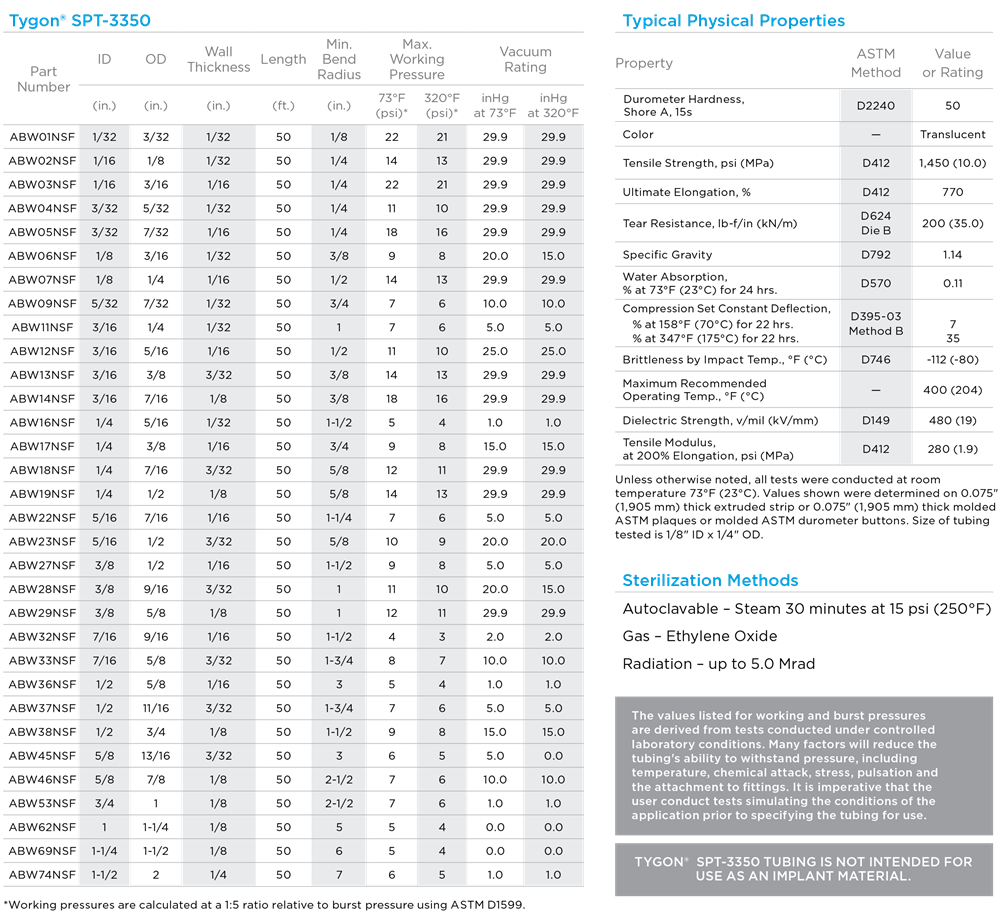

- Complete inventory of standard sizes available, including metric sizes

Typical Applications

- Food and beverage dispensing Regulatory Compliance

- FDA 21 CFR 175.300

- NSF 51 certification