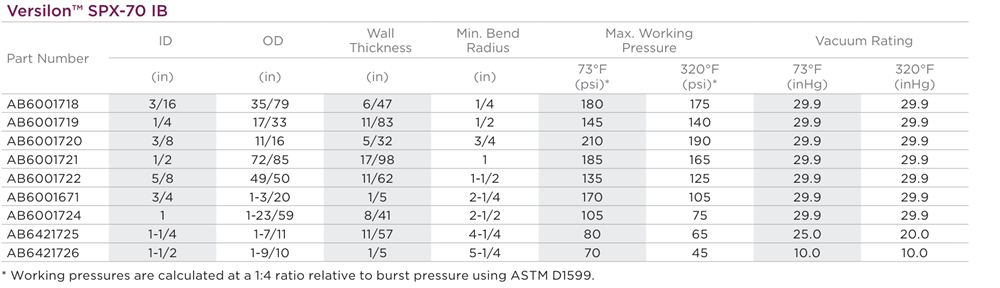

Versilon SPX-70 IB

Reinforced High Tensile Strength Silicone Tubing |  |

Designed for Demanding Requirements

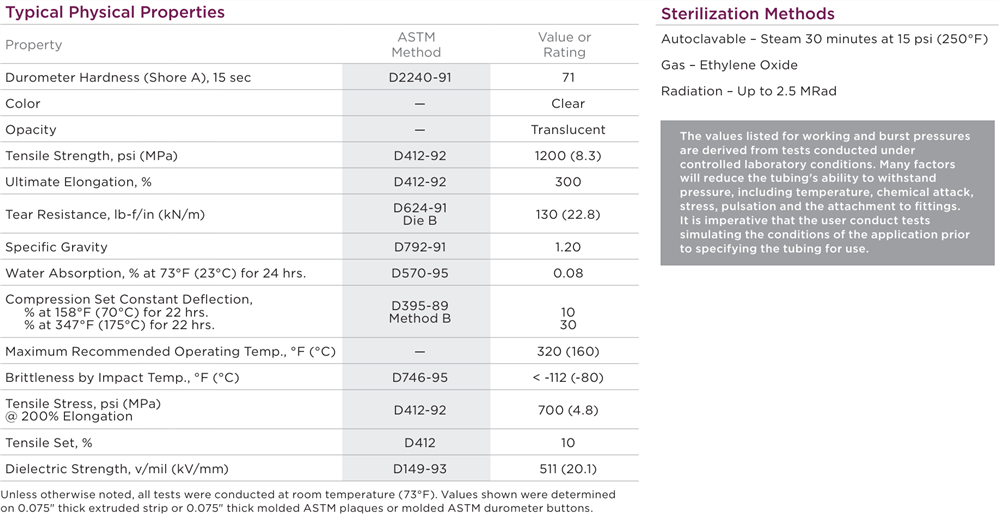

Peroxide-cured Versilon SPX-70 IB tubing is designed for use in applications where flexibility, resiliency and durability are required. Produced from a proprietary combination of silicone elastomers, this tubing optimizes critical physical properties such as tensile strength, elongation and compression set, resulting in a more physically durable product. Its smooth inner surface reduces the risk of particulate entrapment and microscopic buildup during fluid transfer.

Consistently Reliable Results

Every lot of raw material used in the manufacture of Versilon SPX-70 IB silicone tubing undergoes a series of in-house physical property testing before use. This stringent evaluation of ingredients helps to provide the repeatable quality found in every foot of Versilon silicone tubing. Tubing sample testing is performed every year. Heavy metals extraction analysis, as well as, cytotoxicity testing is performed to confirm the tubing’s biocompatibility.

The Leader in Silicone Tubing Innovation

Versilon SPX-70 IB tubing provides versatility in use for a broad range of applications. However, for situations requiring uniquely engineered properties, Saint-Gobain Process Systems can design a tubing formulation suited to meet your specific needs. Specialty formulations may be designed to provide a combination of features – including ultra-high temperature resistance, electrical conductivity, closed cell sponge, pigmented colour, and long flexural life.

Features and Benefits

- Provides resiliency, long-life, and durability

- Ultra-smooth inner bore reduces risk of particulate entrapment

- Tough braid reinforcement permits use under elevated working pressures

- Taste and oder free

- Withstands repeated CIP and SIP cleaning and sterilization

- Temperature resistant from -80°C to 160°C

Typical Applications

- Sterile filling and processing

- Water purification systems

- Cosmetic production

- Beverage dispensing

- Food and dairy processing

- High temperature chemical processing

- Sanitary fitting assembly

Regulatory Compliance

- NSF-51

- FDA 21 CFR PART 177.2600